How to Take Measurement of a Box and Packaging Dimensions

There are different ways of taking a measurement of a box. You can use a ruler to measure the length, width, and height of the box. In this blog post, we will discuss tips on how to get the most accurate measurement possible. So, whether you are an online seller who needs to package their products or you are just curious about how to take measurements of a box, read on for more information!

It's easy to measure a box, right? However, for bespoke packaging, these measurements are crucial in determining the safety of your goods! Box dimensions are an important element of any package since they influence the number of materials required, production costs, and shipping and storage expenses. Consider this analogy: If there is little movement space in the box, there will be less room for damage and increased manufacturing costs. It's true that accurately measuring a box for custom packaging is more difficult than it appears at first sight.

We've put up a list of the most important questions and answers for sizing your box.

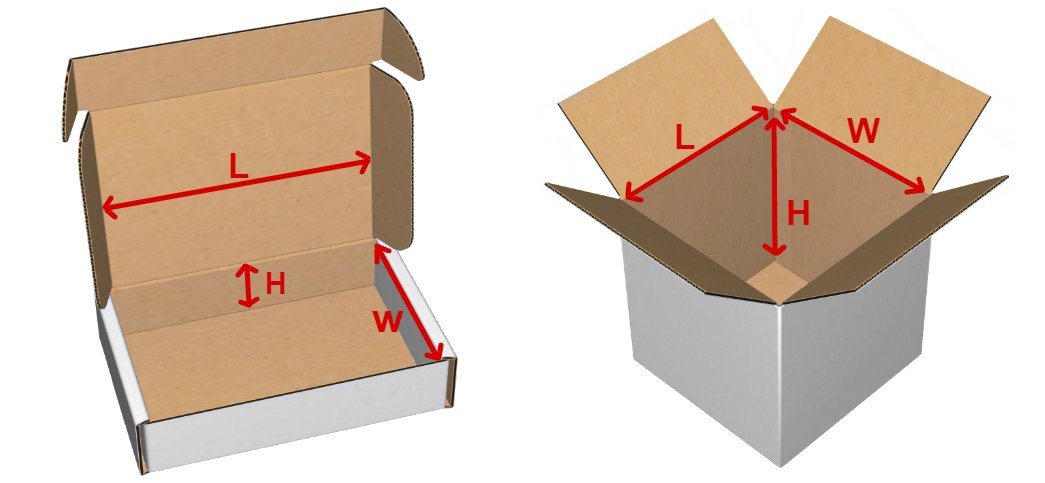

The Three Dimensions in the Measurement of a Box

The first step in producing a flawless package is to ensure that you measure the dimensions of a box correctly. While this may appear to be quite simple arithmetic, accurately measuring your measurements might need some strategy.

So, what precise measurements are necessary?

The three primary dimensions of boxes are length, width, and depth. To get started, take a look at the box's top opening to obtain the following measurements.

Length: When viewed from the top of the box, the longest side is this one.

Width: The shorter of the two sides when viewing the top of the box.

Depth/Height: The side parallel to the length and width.

The depth of a long or upward-facing box is the most important measurement, with length and width being lesser.

Square boxes are frequently not equal in length in the packaging industry. As a result, be sure you measure each feature carefully to ensure your packaging is appropriate for your products. When compared to the length, depth, and width of a big box, which are shown below, they are considerably less.

The sort of box you select is determined by the form and size of your product. Regardless of the type of box, however, production requirements will always be determined by length, width, and depth.

The Importance of Internal Dimensions

Internal dimensions are the industry standard for box measurements. Internal and external dimensions are significant because they influence how well your items fit into packaging. Both manufacturers and their products benefit from internal dimensions since they are more precise.

The majority of manufacturers are particularly picky about the size of their dimensions both internal and external, for good reason. After all, no one wants their items to get harmed as a result of incorrect measurements. While it may appear easier to measure the exterior dimensions of a box, the interior dimensions are what matters most when it comes to creating your bespoke packaging solution. This assures that your goods can actually fit inside the box while allowing you to customise the measurements to guarantee safe transport.

When shipping and storing your items, keep in mind that some movement is necessary. This will guarantee the safety of your products during transportation and handling, allowing you to provide superior quality goods every time.

Sorting Out the External Dimensions

If the measurement of a box is taken from its external dimensions, it may be difficult to pack because the thickness of a box isn't taken into account, which might result in packaging that doesn't quite fit. This might damage specific items if the packaging is not tightly fitted. As a result, calculating the measurement of a box using internal measurements eliminates any uncertainty.

Corrugated boxes are made of two paperboards with a fluted texture woven between them, which makes the material thicker and adds a few millimetres to each measurement taken from the box's external surface. This is why the internal dimensions will give you more precise measurements, making it easier to determine how big you'll need to package your products.

Calculating the Volume of a Box

The volume will assist you in more easily determining your shipping, warehousing, and distribution procedures. It will also aid you in determining how well your product fits into the packaging you want. The volume is critical for material and cost savings as well as structural engineering of your packaging.

So, be sure not to skip over this step

The volume of your container may now be easily determined after you've established its basic dimensions. Simply multiply the three dimensions to obtain a volume value.

Length x Width x Depth = Volume